Maintenance and Spare Parts Management

Maintenance

Basically,

there are two types of maintenance carried out in a factory (manufacturing

unit) for the plant and machinery installed and used therein. These are:

1.

Breakdown

maintenance, and

2.

Preventive

maintenance.

In this case the production facility is run without much routine

maintenance until there is breakdown. Once there is a machine breakdown it is

taken for repair and inspected to find out the defects. After identifying the

defect, the required repair is planned and the spares are procured to repair

the machine. As the breakdowns are random in nature and the machine cannot be

used during the repair period, production hours are lost and hence the

productivity is reduced. Breakdown repair maintenance is not a recommended

practice, in general, but many a time many organizations prefer this, because

they do not want to keep the machine idle for maintenance. But they ignore the

fact that the breakdown repair costs more than the regular maintenance

practice. It is however, an economical way of maintaining certain non-critical

items whose repair and down time costs are less this way than with any other

system of maintenance.

A system of scheduled, planned or preventive

maintenance tries to minimize the problems of breakdown maintenance. It locates

weak parts in all equipments, provides them regular inspection and minor

repairs thereby reducing the danger of unanticipated breakdowns. The underlying

principle of preventive maintenance is that prevention is better than cure. It

involves periodic inspection of equipment and machinery to uncover conditions

that lead to production breakdown and harmful depreciation. The system of preventive

maintenance varies from plant to plant depending on the requirement of the

plant. Any company, adopting the preventive maintenance should keep the record

of failure of various components and equipment, which help the maintenance

department to statistically analyze the failure pattern and replace the item

before it fails, so that the breakdown can be eliminated. This reduces the

number of unanticipated breakdowns, increases the availability of the equipment

for production purpose, and maintains optimum productive efficiency of

equipment and machinery. This also reduces the work content of maintenance job,

and increases productivity and safety of life of worker.

Production department or maintenance department

depending on the size of the plant generally takes up preventive maintenance

work. As the preventive maintenance is a costly affair, it is better to

maintain records of cost (labour, materials used and spares used) and do the valuation

of the work done by the maintenance department so that it can be analysed what

benefits are derived from preventive maintenance. The analytical approach to

evaluate the work done by preventive maintenance is:-

i.

[(Inspections incomplete) / (Inspections scheduled) ×

100] should be less than 10%.

ii.

[(Hours worked for maintenance) / (Scheduled hours) ×

100] = Performance of the department.

iii.

Down time to be given as a ratio of the available

hours and to be compared against a standard to be worked out for each company

or against a figure of the past. The ratio is given as:

= Down time in hours / Available hours (where

Available Hours = working days × hours per day × number of machines). Here down

time is the total time of stoppage of the machine for scheduled and unscheduled

maintenance work.

iv.

Frequency of breakdowns = (Number of break downs) /

(Available machine hours)

v.

Effectiveness of planning = (Labour hours on scheduled

maintenance) / (Total labour hours spent on maintenance).

OR

= (Down time due to scheduled

maintenance) / (Down time due to total maintenance work)

Advantages of preventive maintenance:

i.

Reduced breakdowns and downtime,

ii.

Greater safety to workers,

iii.

Fewer large scale repairs,

iv.

Less standby or reserve equipment or spares,

v.

Lower unit cost of the product manufactured,

vi.

Better product quality,

vii.

Increased equipments life, and

viii.

Better industrial relations.

Spare Parts Management

In

manufacturing plants that own a huge number of equipment and machineries,

supervising the spare parts correctly and in a timely manner is a difficult

task. Usually, spare parts are categorized into two main groups

• Fast moving parts, and

Fast moving spares are those

that are usually required quite frequently, and slow moving spares are those

that are hardly ever required. The managers come across difficulties in keeping

track of the spare parts used and in determining their future demand manually.

The main objective of this project is to create a database management system

that will help the managers with the process of supervising spare parts. The

system should be designed in such a way that it will be able to

(a)

Keep record of the spare parts required for a

particular type of maintenance;

(b)

Keep record of the spare parts received and used in

the past;

(c)

Schedule forthcoming major maintenance services;

(d)

Keep record of spare parts vendors;

(e)

Forecast future demand for fast moving spare parts

based on past consumptions; etc.

Preventive maintenance is very important but failures

cannot be eliminated completely. To avoid and minimise the occurrence of failures

spare parts management play a vital role. Failure statistics are useful in calculating

spare parts requirements for preventive maintenance as well as breakdown maintenance.

Types of Spare Parts

These spare parts are required

regularly and in substantial number. Both reliability and per unit cost of

these items are less.

An insurance spare is a spare

part that is held in spare parts inventory that would not be expected to be

used in the normal life of the plant and equipment but if not available when

needed it would result in significant losses.

Capital

spares are spare parts which, although acknowledged to have a long life or a

small chance of failure, would cause a long shutdown of equipment because it

would take a long time to get a replacement for them.

Rotable items are generally

thought of as items of plant or assets that periodically are changed out for

repair or overall. The management of rotable items

and repairable spare parts is different to the management of other inventory

items and proper control requires greater cooperation between maintenance and

stores/inventory management. The successful management of these items is far

more active than other spare parts as maintenance and store / inventory personnel

must work together to ensure that there is visibility of the status of items.

Part B

Illustration: 1

A workshop has 20 nos. of identical machines. The failure pattern of the

machine is given below:-

|

Number

of months |

Probability

of one breakdown of a machine |

|

1 |

0.20 |

|

2 |

0.15 |

|

3 |

0.15 |

|

4 |

0.15 |

|

5 |

0.15 |

|

6 |

0.20 |

It costs Rs 150 to attend a failed machine and rectify the same. Compute

the yearly cost of servicing the broken down machines.

Solution: 1

Illustration: 2

A Public transport system is experiencing the following number of

breakdowns for months over the past 2 years in their new fleet of vehicles:-

|

Number

of breakdowns per month |

0 |

1 |

2 |

3 |

4 |

|

Number

of months this occurred |

2 |

8 |

10 |

3 |

1 |

Each break down costs the firm an average of Rs 2,800. For a cost of Rs

1,500 per month, preventive maintenance can be carried out to limit the

breakdowns to an average of one per month. Which policy is suitable for the

firm?

Solution: 2

Illustration: 3

A company has 50 identical machines in its facilities. The cost of preventive servicing (CP) is Rs 20, and the cost of repair after breakdown (CR) is Rs 100. The company seeks the minimum cost preventive servicing frequency and has collected the data on breakdown probabilities in the following table:

Probabilities

of machine breakdown

After months after servicing:

|

Months after servicing (i) |

Probability

of breakdown (Pi) |

i × Pi |

|

1 |

0.10 |

0.10 |

|

2 |

0.05 |

0.10 |

|

3 |

0.05 |

0.15 |

|

4 |

0.10 |

0.40 |

|

5 |

0.15 |

0.75 |

|

6 |

0.15 |

0.90 |

|

7 |

0.20 |

1.40 |

|

8 |

0.20 |

1.60 |

|

å |

1.00 |

5.40 |

Solution: 3

Illustration: 4

A large computer installation

contains 2,000 components of identical nature which are subject to failure as

per probability distribution that follows:

|

Month

end: |

1 |

2 |

3 |

4 |

5 |

|

%

Failure to date: |

10 |

25 |

50 |

80 |

100 |

Components which fail have to be replaced for efficient functioning of the system. If they are replaced as and when failures occur, the cost of replacement per unit is Rs 3. Alternatively, if all components are replaced in one lot at periodical intervals and individually replace only such failures as occur between group replacements, the cost of component replaced is Rs 1.

Required:

(a)

Assess which policy of replacement would be

economical.

(b) If group replacement is economical

at current costs, then assess the cost of individual replacement that would

make group replacement uneconomical.

(c) Assess how much high can be the

cost per unit in group replacement to make a preference for individual replacement policy.

Solution: 4

Illustration: 5

An electric company which generates and distributes

electricity conducted a study on the life of poles. The repatriate life data

are given in the following table:

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

|

|

1 |

2 |

3 |

5 |

7 |

12 |

20 |

30 |

16 |

4 |

Required:

1. If the company now installs

5,000 poles and follows a policy of replacing poles only when they fail, how

many poles are expected to be replaced each year during the next ten years? To

simplify the computation assume that failures occur and replacements are made

only at the end of a year.

2. If the cost of replacing

individually is Rs 160 per pole and if we have a common group replacement

policy and it costs Rs 80 per pole, find out the optimal period for group

replacement.

Solution: 5

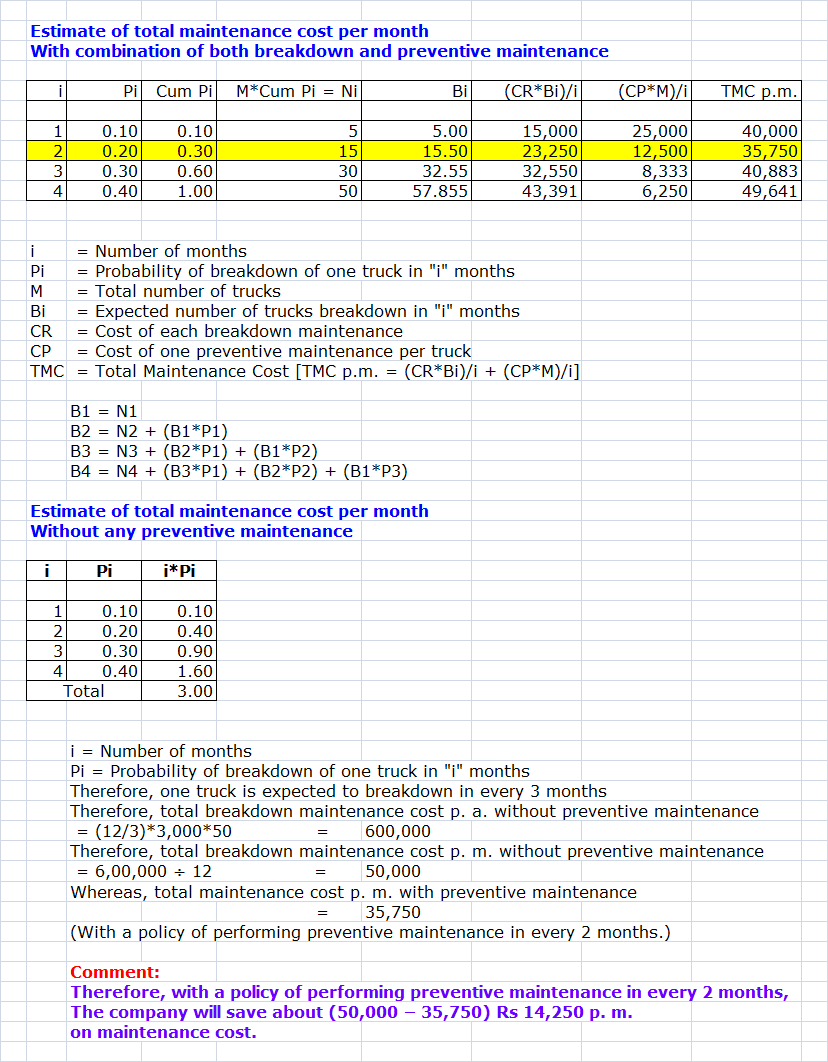

Illustration: 6

Maharashtra Trucking Company (MTC)

has a fleet of 50 trucks. The past data on the breakdown of the trucks shows

the following probability distribution (for a new truck as well as for one

which has been repaired after a breakdown).

|

Months after Maintenance |

Probability of Breakdown |

|

1 |

0.10 |

|

2 |

0.20 |

|

3 |

0.30 |

|

4 |

0.40 |

Each breakdown costs Rs 3,000 on an average; which

includes cost of time lost and cost of materials and manpower.

The manager of MTC knows the

importance of preventive maintenance. He estimates the costs of the preventive

maintenance to be Rs 500 per such preventive action. What should be the

appropriate maintenance policy in terms of the mix of preventive maintenance and

breakdown maintenance?

Solution: 6

I read this article thoroughly and i understood each and everything. It is very helpful for my upcoming exam.

ReplyDeleteit was so much helpfull,thank you so much

ReplyDelete